Introduction

On 10 May 1997, the

"JEANNIE," on a voyage from Boulogne, France, was bound for Montreal,

Quebec. The vessel, under the conduct of a pilot, was abeam of Lotbinière,

Quebec, when the bridge watch realized that the rudder angle indicator was hard-a-port.

They tried in vain to bring the vessel back on course by changing the steering

gear mode from the steering position on the bridge. At approximately 2255, the

"JEANNIE" grounded on the south edge of the channel in the approaches

to buoy Q83, before the anchor could be let go or the main engine put astern.[3]

After the grounding, the tanks were sounded

and it was found that only the forepeak was holed. The vessel's pumps were

unable to reduce the level of water in the tank below the waterline forward.

On May 11, at approximately 0700, two tugs

departed the Port of Québec to assist the bulk carrier. At approximately 1010,

as the tugs arrived on the scene, the vessel refloated herself on the rising

tide. At 1043, the vessel advised the Quebec Marine Communications and Traffic

Services that she had refloated and was anchored on the north side of the

channel.

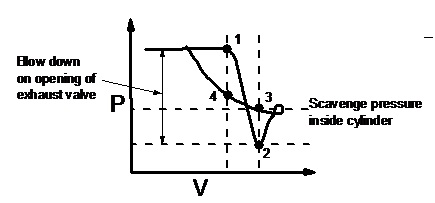

The steering gear of the

"JEANNIE", manufactured by Donkin & Co. Ltd., is of the

articulated-cylinder type. The gear consists of two units, each including two

double-action cylinders. Each unit is fitted with a constant-speed pump. These

pumps are mounted on a single hydraulic fluid reservoir. A multiple-valve

collector isolates either of the units for maintenance or emergency manual

operation.

Accident Analysis

Breaking of a Hydraulic Hose

Visual inspection of the hydraulic hose

showed that it was hardened and cracked and that it had separated from the

coupling. The deterioration of the hose is attributable to the surrounding

sources of heat and wear. When a break occurs on a hydraulic component, the

single reservoir quickly empties its contents because of the constant-speed

pumps.

Alarms

When the amount of hydraulic fluid in the

reservoir drops to a predetermined level, an alarm sounds in the engine control

room. A crew member has to go into the steering gear compartment, identify the

problem, shut off four valves using a special wrench, and then open two other

valves to isolate the unit in trouble and thereby restore steering capability

to the vessel. When the first person arrived in the steering gear compartment,

the hydraulic fluid reservoir was already empty; thus, nothing could be done to

counter the failure.

The low-level alarm apparently sounded in

the engine control room. On the bridge, it was noticed that something was wrong

when the rudder-angle indicator read hard-a-port and the helmsman could not

return the helm amidships despite his efforts. The alarm was apparently not

heard by the personnel on the bridge.

Reservoirs

In spite of the direct access to the

steering gear compartment from the engine-room, the system was designed in such

a way that it would have drained completely even with the intervention of an

engineer. The two units are supplied by a single reservoir and there is no

storage tank permanently connected to the hydraulic system. Had each of the

units been fitted with an independent reservoir, the steering gear would have

remained in operation without intervention by the personnel. On some of the

more-recently built vessels, the steering gear remains in operation even when

one of the units fails.

Regulations

Canadian regulations require that in the

event of a failure, steering capability be maintained or speedily

restored. The requirements are more stringent, however, for tankers and

chemical tankers of over 10,000 gross tons. Such vessels have to be able to

restore steering capability less than 45 seconds after failure of a power

transmission system. In confined waters, all vessels should be able to regain

steering capability in the event of failure regardless of their size or type.

Several domestic and foreign tankers and chemical tankers of less than 10,000

gross tons that transit the St. Lawrence River and other confined waters

in Canada are not subject to these requirements.

The loss of hydraulic fluid from one of the

systems must be able to be detected and isolated automatically so that another

system or systems can remain operational.

The International Convention for Safety

of Life at Sea (SOLAS), Ch. II-1, Part C,

contains regulations for steering gear that are adopted by some classification

societies and are also found in the Canada Shipping Act. These

regulations apply to all convention vessels. Some of them read as follows:

Regulation 29, Art. 1:

. . . [t]he main steering gear and the auxiliary steering gear shall be so

arranged that the failure of one of them will not render the other one

inoperative.

Regulation 29, Art. 6.1.3:

. . . the main steering gear is so arranged that after a single failure in its

piping system or in one of the power units the defect can be isolated so that

steering capability can be maintained or speedily regained.

Regulation 29, Art. 12.2:

. . . a low-level alarm for each hydraulic fluid reservoir to give the earliest

practicable indication of hydraulic fluid leakage. Audible and visual alarms

shall be given on the navigating bridge and in the machinery space where they

can be readily observed; and

Regulation 29, Art. 12.3:

. . . a fixed storage tank having sufficient capacity to recharge at least one

power actuating system including the reservoir, where the main steering gear is

required to be power-operated. The storage tank shall be permanently connected

by piping in such a manner that the hydraulic systems can be readily recharged

from a position within the steering gear compartment and shall be provided with

a contents gauge.

2.5 Compatibility with International

Requirements

Where the main steering gear comprises two

identical power units, it should have the same capability and reliability as a

main power unit fitted with an auxiliary steering gear, and be capable of being

brought into operation from a position on the navigation bridge. In the event

of a power failure to either of the steering gear power units, an audible and

visual alarm must be given on the navigation bridge.

The steering gear of the

"JEANNIE" met regulatory requirements at the time of its

construction. This type of steering gear, in use on both foreign and Canadian

vessels, can be modified to prevent such a failure.

Conclusions

Findings

A steering gear hydraulic system hose

separated from its coupling, causing the hydraulic fluid reservoir to empty.

The crew could not intervene in time to

isolate the defective power unit.

A single reservoir supplied both steering

gear units, and there was no storage tank permanently connected to the

hydraulic system in such a manner that the system could be speedily brought

back into operation.

No audible or visual alarm indicating the

problem was noticed by the crew on the bridge.

Following the failure of her steering gear,

the "JEANNIE" grounded, causing damage to her forepeak.

This type of steering gear is in use on

both foreign and Canadian vessels.

Causes

The "JEANNIE" ran aground because

a steering gear hydraulic hose failed and the crew of the vessel could not

intervene and regain steering control before the two power units became

inoperative.